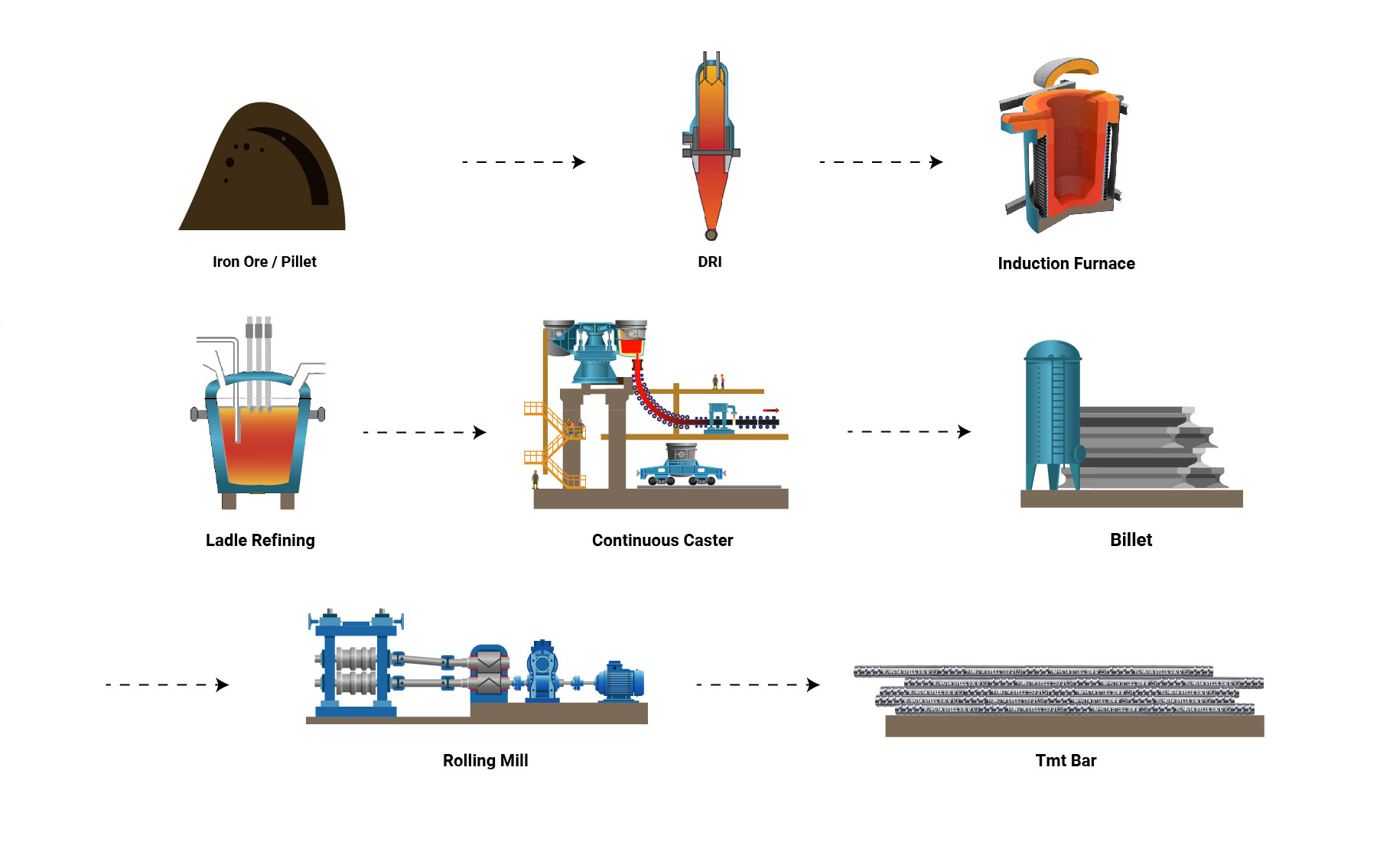

Rungta Steel TMT Bars are designed with the aim of contributing to the construction of a stronger India by providing excellent strength and reliable performance. These bars are manufactured using a meticulous process that involves the careful selection and utilization of high-quality raw materials. The raw materials used in the production of Rungta Steel TMT Bars undergo thorough quality analysis to ensure that they meet stringent standards.

By employing advanced manufacturing techniques and quality control measures, Rungta Steel ensures that their TMT bars are of the best-in-class quality. These bars adhere to all relevant quality standards, ensuring that they deliver exceptional performance and reliability in various construction projects. With their high tensile strength, superior ductility, and excellent bonding characteristics, Rungta Steel TMT Bars effectively resist the forces exerted on structures due to factors like heavy loads, seismic activities, and environmental conditions. This helps in preventing structural failures, ensuring the safety of the people and assets relying on these structures.

The primary objective of Rungta Steel TMT Bars is to reinforce and strengthen all types of construction structures, thereby enhancing their stability and security. These bars are extensively utilized in critical infrastructure projects such as airports, flyovers, ports, and metro subway tunnels. By incorporating Rungta Steel TMT Bars into these projects, the structural integrity and durability of the nation’s infrastructure are significantly improved.

Post the production stage, these products pass through a series of stringent quality tests to ensure unparalleled stability, longer durability and seamless workability. With the ISO and OHSAS certifications, the company promises to meet the varied requirements of the construction industry.

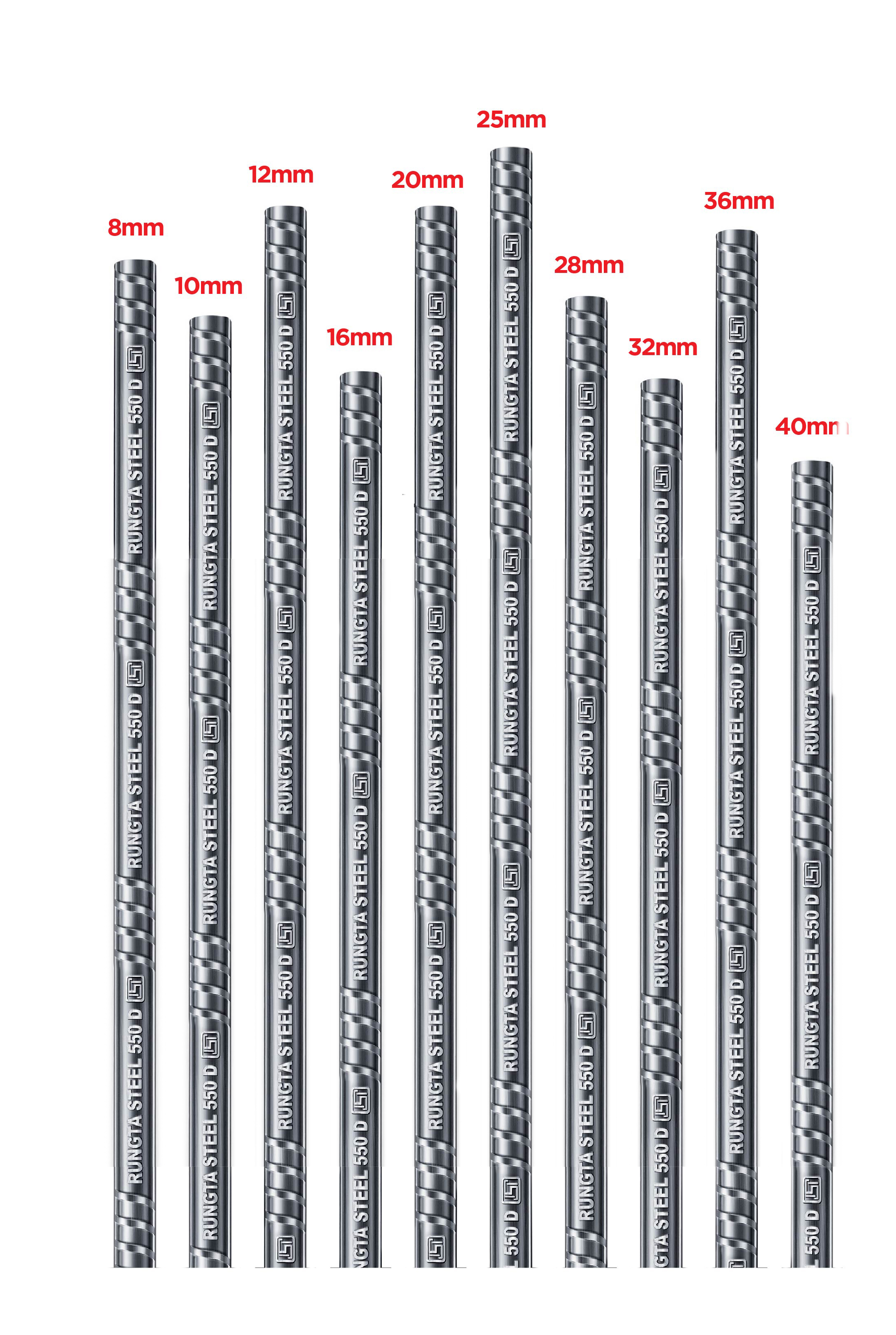

Rungta Steel TMT Bars come in grades of Fe500, Fe500D, Fe550 & Fe550D as per IS 1786

and sizes of 8/10/12/16/20/25/28/32/36/40 mm

Top grade raw materials are used allowing superior malleability which makes them highly shock resilient.

Consistency is the key which makes these TMT bars the best in the market with uniform parallel rib patterns.

Purity and longevity at its best is seen, since steel is processed using state-of-the-art technology and innovation.

Porous free uniform surface and low carbon content allows high weldability of these TMT bars without the doubt of being broken.

High UTS/YS indicates a high strain hardening rate beyond yield point – a requirement for EQR steel providing maximum protection in case of an earthquake.

Additional area under the curve allowing extra energy to be dissipated before breaking meeting the International Standards of fatigue strength.

Loses only 5% of tensile strength when exposed to a temperature of 400°C for an hour, but again regains it back as soon as the temperature comes down.

The tensile-to-yield strength ratios are always greater than 1.15.

Best in class raw materials used during the extensive process of production to manufacture the cleanest steel.

Smooth surface and minimal to no porosity in the steel products increases weldability outruling any breakages.

State-of-the-art integrated steel plants to increase production capacity in line with the government’s target to reach 300 MTPA by 2030.

Rungta Steel TMT Bars are made with a vision to impart great strength and superior reliability for the construction of a stronger India. This is achieved through proper usage of raw materials, identified through proper quality analysis essential to achieve the best-in-class product adhering to all quality standards.

Reinforcing and strengthening all construction structures to move towards greater stability and security. Rungta Steel TMT bars are used across airports, fly-overs, ports and metro subway tunnels to enhance the structural integrity of the nation.

In summary, Rungta Steel TMT Bars are specifically engineered to meet the demands of modern construction, aiming to strengthen the infrastructure of India. Through their commitment to quality and adherence to industry standards, Rungta Steel TMT Bars provide the necessary reinforcement and stability required for constructing robust and secure structures, ultimately contributing to a stronger and more prosperous nation.

Have a query? Need specialised help? Contact us and our

customer care representative will get back to you.